For years, screen printing has been one of the most popular methods of labeling lightweight clothing with a predominance of cotton. Mainly used on T-shirts or polo shirts, but it can be successfully used to mark business shirts or sweatshirts. In the whole range of different decorating methods, screen printing is characterized by the greatest durability of the graphics made and relatively low cost for large print runs. Despite a certain amount of technological limitations, this is a method that you should definitely consider when considering ordering T-shirts with a logo for your company. The following text will certainly bring you closer to the details of this technique of screen printing in Dallas, explaining what screen printing is.

What is screen printing?

Screen printing, which is the colloquial name of screen printing or serigraphy, is a printing technique in which the printing form is a template imposed on a fine woven mesh, metal or made of synthetic fibers . Making a print consists in forcing the paint through the matrix, guaranteeing full reproduction of the source file. Currently, it is one of the most popular marking methods, allowing for the implementation of large quantities in a relatively short time.

Screen printing is classified as a direct marking method, which means that it is placed directly on the garment without any external carriers.

Screen printing can be successfully used to decorate various types of substrates such as wood or plastic. The condition for screen printing is a flat, uniform surface. However, let’s focus here on the aspect typically associated with the marking of textile materials.

Screen printing – a short history

Screen printing technology originated in the 17th century from the stencil printing methods used by the Japanese to decorate kimonos, where the pattern was cut on paper and applied to a special mesh made of human or animal material stretched over a wooden frame. The later stages are continuous technological development, improving the production process. In 1907, Samul Simon made and patented a matrix made of silk cloth, partly covered with varnish, calling the technique ‘Silk-Screen’ known today as screen printing.

Contemporary technology

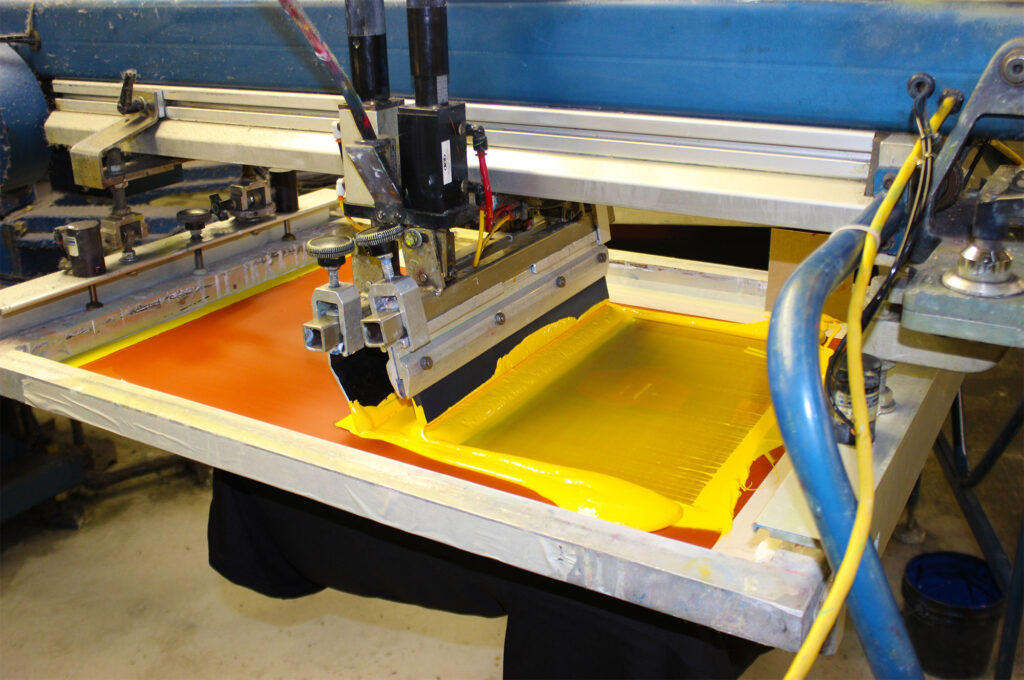

Initially, the screen printing process was carried out using a press, the operation of which was purely manual, so the ink had to be pressed manually using a squeegee through the matrix into the target material. Technological progress has also affected screen printing and today, thanks to automation, this process has undergone a number of improvements and currently the so-called labels are used for marking. carousels – fully automated machines with a hydraulic press for injecting the dye, allowing for much faster implementation of projects than the traditional manual method.

Screen printing – durability and application

Screen printing technology is a very durable method of printing a print on clothing . Often confused with ‘iron-presses’ known from the beginning of this century, whose durability was limited to one-time use. The process of screen printing itself consists in forcing the paint into the material, thanks to which it creates a uniform whole with clothing, while guaranteeing high color durability and resistance to washing and abrasion. Most often used to mark lightweight cotton garments such as a T shirt or polo shirt . However, it is also used in other areas than textiles.

When ordering clothing made with screen printing, you can be sure that the design will be made in accordance with the sent file , and the print will be permanently applied to the clothing. This is a very good solution for large-area graphics, thanks to which the T-shirt is not stiffened by a sheet of foil, as would be the case with thermal transfer printing. This significantly increases the comfort of wearing such clothing, especially during hot days.

Screen printing allows for the implementation of large volumes in a short time at a relatively low unit cost, especially for one-color logotypes where only one color matrix is to be made. Making smaller print runs is not an obstacle for screen printing, but the costs of production preparation, including matrices, are less profitable than for other methods of clothing marking.

Advantages and disadvantages of screen printing

Following the popular idea ‘the more the cheaper’, screen printing accurately reflects the meaning of the above saying. This technique is ideal for making very large quantities of clothing, while guaranteeing a gradually lower price.

Of course, we also use it to mark smaller quantities, although in this case the price is no longer a strong point of the above technique. Nevertheless, the durability that we achieve in the end is worth every penny!

Thanks to a large number of paints, it is possible to obtain extremely expressive and fully saturated colors, which is an undoubted advantage, but it entails a certain limitation as to the number of colors used in marking. We are able to obtain 5 color shades for one logotype. This involves the need to prepare a matrix for each color, which generates additional costs, especially noticeable in smaller print runs. Also tonal transitions are usually unified to one color. It is possible to reproduce them using raster screen printing, at which the pressure on the matrix is variable, giving the effect of color refraction.

The screen printing method is an extremely durable method of marking , paint manufacturers guarantee the durability of the logotype even when washing at 90 degrees – of course, no cotton t-shirt will survive such a test, so with the right care process, i.e. washing at the temperature indicated on the product label, it will allow the t-shirt to be used for many years with screen printing.

Screen printing, as one of the few methods , is almost free of defects , poses certain production limitations, although it offers much more benefits from its use.

Screen printing cost

The cost of screen printing is primarily influenced by the following three factors

- The size of the graphics – however, it is unified from the matrix formats necessary for preparation, we distinguish 3 basic formats – A5/A4 and A3.

- Number of colors – we are able to make 5 colors for one graphic, but each color is associated with an increase in the unit cost and the preparation of the appropriate matrix

- Quantity of clothing – as we have already mentioned several times, the price of screen printing is most determined by its quantity. The price for quantities below 50 pieces can be even several times higher than for 1000 pieces.

Screen printing clothing care

Despite the high durability of the screen print, it is necessary to take into account the appropriate process of clothing care, which will allow for the longest possible maintenance of the applied graphics in their original form.

Despite the resistance of screen printing to higher washing temperatures, you need to remember about the material on which it was made to ensure its durability. The optimal washing temperature for screen printing shirts is 40 degrees Celsius . First of all, it guarantees the preservation of the original shape and color of clothing, and additionally reduces the possibility of paint chipping during a long-term washing process at high temperatures. When ironing, do this on the inside of the T-shirt and avoid ironing directly after screen printing to avoid cracks caused by the high temperature of the iron.

What is the screen printing process like?

The first element that begins each screen printing process is the preparation of an appropriate matrix , i.e. a rectangular frame with a stretched mesh called a sieve made of nylon or metal, on which the target print template is placed.

The stencil itself consists in covering the non-printing places – i.e. blocking the mesh openings, thanks to which we obtain a pattern that will be transferred to the T-shirt. Then, a print is made consisting in transferring the paint using a squeegee through a prepared template. Under special pressure, the paint is pressed directly into the fabric of the garment, without the use of any additional adhesives.

The matrices prepared are disposable, and it is necessary to prepare a matrix that is necessary for each color contained in the logotype and for each size. For example, when marking a logo containing three colors on the chest and back, it is necessary to prepare as many as 6 matrices. Therefore, the cost of small print runs is much higher than the use of digital printing.

Marking clothes with screen printing is done with the use of special paints. Currently, the most popular on the market are plastisol and water based inks. Their color selection is described using the Pantone palette, which does not have such a wide range as CMYK. When deciding to use screen printing, make sure that your logo is also color-coded in the Pantone palette.

Screen printing – is it worth it?

Definitely yes! Screen printing has become a very desirable technique for marking clothes in recent years and convinces more and more customers. Thanks to its high resistance to care processes and high color durability, it is the main technique we use to mark t-shirts, polo shirts and even cotton shirts.

It is especially recommended for company clothing in production halls, where shirts are washed on a regular basis and must serve for as long as possible.

In the case of graphics that at first glance are not suitable for screen printing, it is worth making a compromise and taking into account some kind of simplification, while gaining an almost indestructible logo on company T-shirts. Low cost of production, high durability and accuracy in mapping logo elements are factors in favor of choosing screen printing as the target method of marking.